ABM Greiffenberger U.S. Subsidiary

Welcome to ABM DRIVES INC.

ABM News

News & Press

Driving the future: You can read all th e news about ABM in our Press area and meet us personally at our trade fairs.

We drive the World

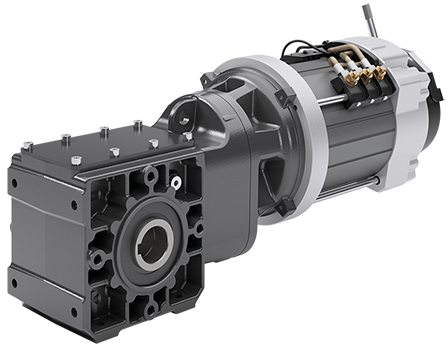

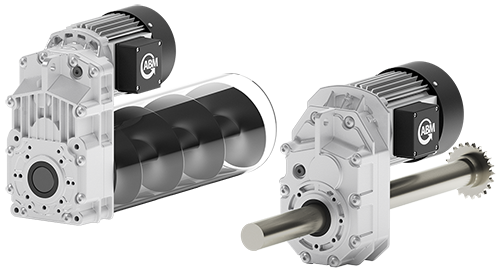

Choosing a Gearbox Drive and Electric Motor Supplier

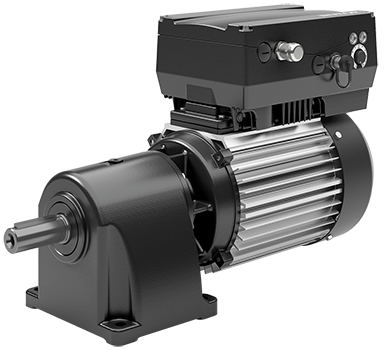

When choosing manufacturing partners during a machine build, remember that there are two methods for choosing a gearbox and electric motor supplier.

One is selecting a pre-engineered unit and the other is choosing a gearbox-motor combination and integrating them into the equipment.

Pre-engineered gearmotor solutions are suitable if a design engineer doesn’t have the time or engineering resources to build a gearmotor in-house — or if the

design needs a quick setup. New modular approaches to support OEMs (and enable new machine tools, automation, and design software) now let engineers get

reasonably priced gearmotors even in modest volumes.

It’s true that one benefit to selecting a separate motor and gearbox and then combining them can less expensive than choosing a pre-engineered gearmotor.

Another benefit to this approach is that one may be able to design the most optimized gearmotor for the application at hand … because this approach also gives the

design engineer the most control over the final configuration and cost.

No matter the approach to gearmotor selection, be sure to continually improve the design by comparing predictions of performance with measurements. Then use

the result of the analysis to improve next gearmotor iteration.

Contact:

ABM DRIVES INC.

Mr. Sandeep Abrol | Managing Director

394 Wards Corner Road · Suite 110

Loveland, OH 45140 | USA

Phone: +1 513 576-1300 Send an email

Fairs & Events

Company News

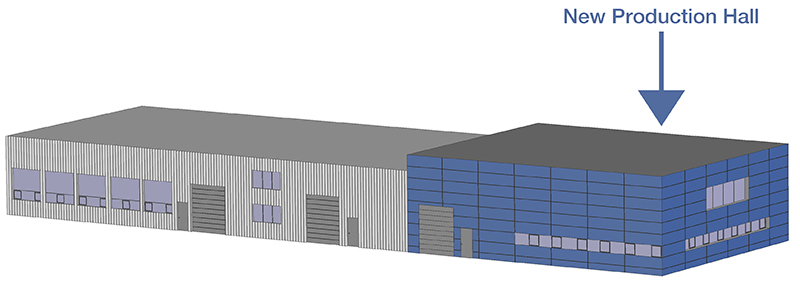

Expansion of the ABM Drives Inc. Marktredwitz Production Site

>Since 2017, ABM has invested in a multi-million dollar capital construction project to improve two ABM manufacturing locations: Marktredwitz (Upper Franconia) and Lublin (Poland). Despite the current difficult times, the initial investment package for the construction of a new, approximate 7,000 sq. ft. production hall “An der Rößlermühle” (Factory 4). This investment also includes new, automated machining centers with test technologies. The commissioning and the installations are planned for March 2021.

“On the one hand, we strengthen the high vertical integration in our core competencies with this capacity expansion. On the other hand, the automated machining centers guarantee reliable production processes and flexibly enable us to meet the demands of the market and our customers,” says Robert Lackermeier, CEO of ABM Greiffenberger. Special thanks go to the architectural firm Wittmann, construction companies Roth and Sybac, and Marktredwitz mayor, Oliver Weigel and his team. They have been involved in the early phases of planning and strongly supported ABM in this construction project, among other things including their swift issuing of the building permit.

“ABM Greiffenberger stresses the importance of the Marktredwitz location with this hall extension,” emphasizes Dr. Werner Folger, sole shareholder and CEO of the senata group. “ABM is geared for growth and optimally equipped for the future.”

The official groundbreaking that had originally been planned for the October 28, 2020 was cancelled due to the increasing number of Corona cases. Instead, there will be an official opening when the new production hall and the machine park will be finished and can be visited. Persons invited to this event will include County Commissioner Peter Berek, Mayor Oliver Weigel, Martin Schöffel, Member of the Bavarian Landtag, as well as further representatives of the companies Wittmann (architectural office), Roth and Sybac (construction companies) and of the city of Marktredwitz.

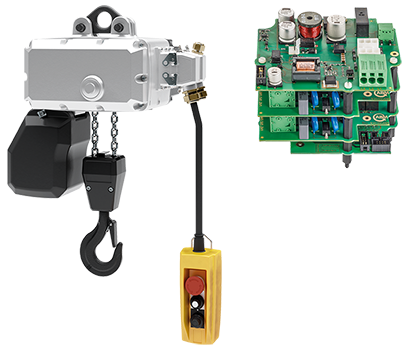

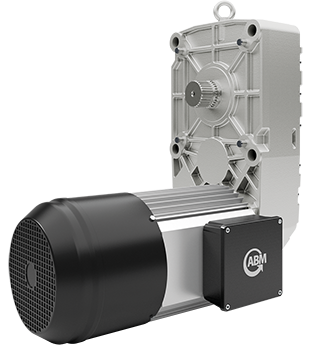

Cranes / Hoists

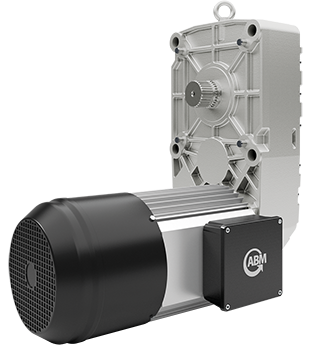

Improved Crane and Hoist Safety With New GH and GHX Lines of Hoist Drive Units and Motors

>ABM DRIVES INC. introduces its latest line of GH and GHX hoist drive units and motors to manage precise and safe lifting of loads ranging from 3.2 to 40.1 tons. These hoist and crane drives deliver safe handling for both the operator and the load by managing precise loads; implementing soft acceleration; integrating smooth, low-wear and dual-surface safety brakes; braking safely without swinging the load; automatically braking during a power loss; and offering aluminum housings with high corrosion resistance.

Additional product highlights include: light weight units for reduced shipping costs and easy mounting; compact designs for small space requirements; increased axle distance for favorable mounting conditions; dynamic speed torque curve for high start and break-down torque; and bearing support of drum integrated into hoist drive gearbox.

ABM DRIVES INC.’s specially designed product program for demanding hoist technology offers a single source for hoist drive units, hoist motors all the way to travel drive units and frequency inverters.

E-Mobility / Material Handling

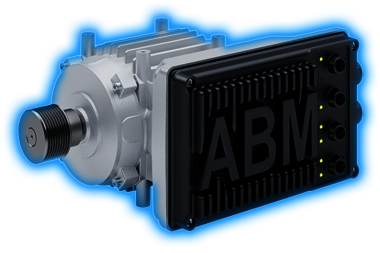

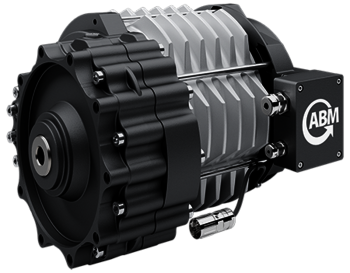

Motors for High Load Peaks and Continuous Performance

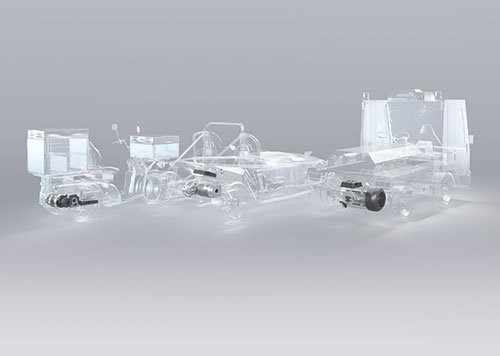

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The adaptable drive solutions consist of motors, gearboxes, brakes and controllers and are developed by the specialist in close partnership with customers.

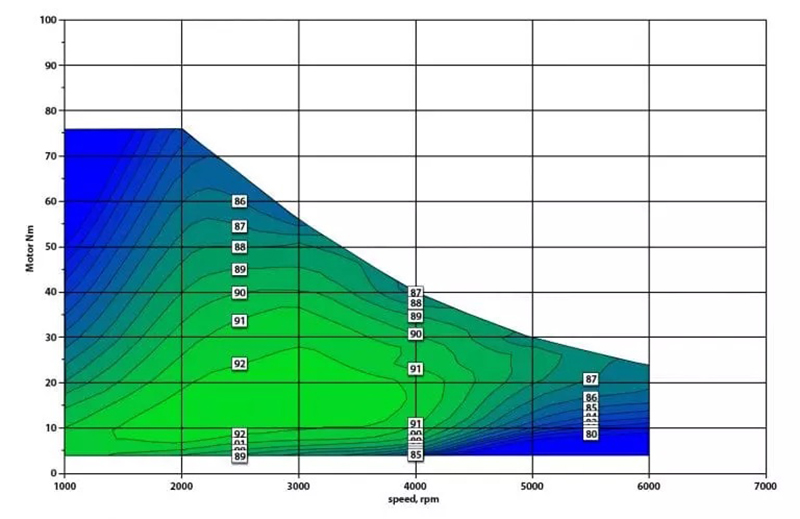

Drives for electric vehicles must meet high expectations: They have to be environmentally friendly, efficient, powerful and inexpensive to maintain. “ABM Greiffenberger already started to transfer its know-how from battery-powered drives to E-mobility before the turn of the millennium and even back then was already able to implement the first projects,’ reports Mayk Krüger, Senior Manager of Material Handling. Users benefit from the full-service provider’s decades of expertise: They receive powerful drives with high efficiencies.

Compared with standard motors, the ABM drives are much more compact – and also extremely robust, durable and maintenance-free in harsh operating conditions. ABM offers a platform concept with manifold options – customers receive cost-optimised, easy-to-integrate system solutions. The drive specialist also adapts the motors to individual customer requirements and applications.

ABM Greiffenberger offers motors for auxiliary units in trucks and buses as well as traction drives for use in a wide variety of electric vehicles. Krüger says: ‘For our AC drives with housings, we have optimised the cooling for longer periods of continuous performance.’ Because the drive is installed on the differential axle at a right angle to the direction of travel, the developers have adapted the ring ribs of the drive appropriately to ensure optimal air cooling. This makes these motors suitable for journeys with high load peaks and high continuous performance. Even in harsh or dirty environments, reliable operation of the on- and off-road vehicles is ensured. Depending on the motor size, peak powers of 20, 50 and 90 kW and torques of 45, 130 and 260 Nm are achieved.

Sensors monitor the motor temperature and record the speed. Speed and torque control is provided via an external AC controller. Upon request, ABM can deliver a parameterised controller as a plug-and-play solution tailored to the application and can also optionally install an electromechanical holding brake. Versions with IP 66 protection rating and UL certification can also be provided.

The drives can be used in all E-mobility applications, including utility vehicles, golf carts and agricultural machinery as well as electric trucks and on- and off-road vehicles. Traction motors for electric vehicles such as baggage tow tractors and airport ground support equipment (GSE) vehicles are additional applications.

ABM offers a platform concept with multiple options.

ABM housing motors for battery-powered vehicles ensure due to the ring-shaped design of the ribs an optimized heat dissipation.

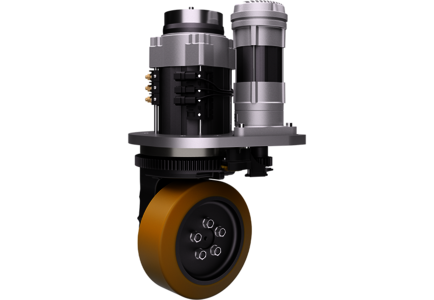

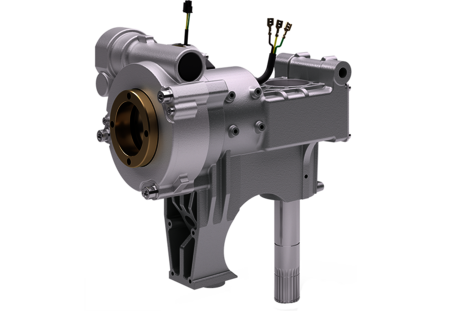

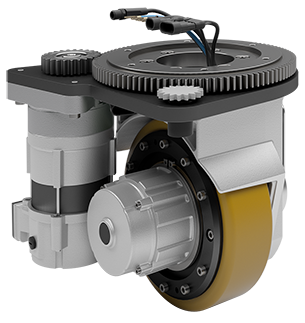

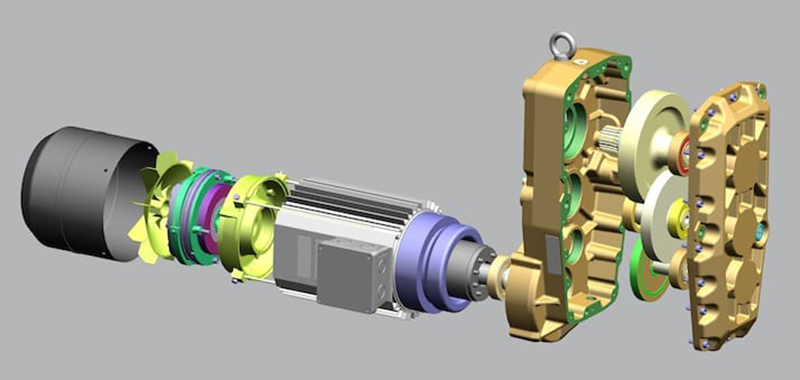

Compact Platform with the Highest Level of Integration

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The drive solutions consisting of motors, gearboxes, brakes and frequency inverters tailored to specific applications are developed by the specialists at ABM Greiffenberger in close partnership with their customers.

‘Traction, lifting and steering in forklift trucks, for example, require both know-how and the right drive components,’ says Mayk Krüger, Senior Manager of Material Handling at ABM Greiffenberger. ‘Our solutions consistently comply with strict environmental requirements, are particularly safe and enable precise movements even at low speeds thanks to their high responsiveness.’

ABM supplies all drive components, including motors, gearboxes, sensors and inverters, from a single source. And that’s not all: The drive specialist develops and manufactures complete gearbox–motor drive units in-house – this system expertise sets the company apart from the competition. With the modular system, ABM is always able to supply the right solution – irrespective of the vehicle type.

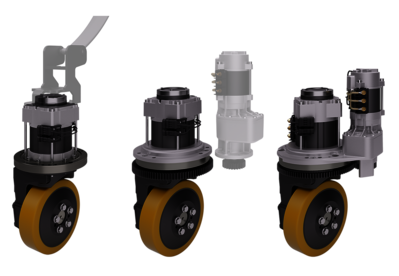

‘Our drives make dynamic movement and precise manoeuvring of industrial trucks possible for users, even in tight spots,’ Krüger says. ‘Also, our solution provides forklift trucks with excellent climbing performance.’ The TDB series can easily be integrated into a given application via plug and play. The two-stage bevel-helical gearbox drive unit offers high performance and low energy consumption. It can be used for both manual and electric industrial trucks. It is characterised by high-power density and outstanding efficiency. Combined with a steering drive and equipped with a fully integrated and reliable sensor monitoring system, it gives the user a fully integrated traction and steering drive solution. ‘Through the vertical design, the small envelope size and the numerous series options, this gearbox drive unit is ideal for a multitude of applications – for example, in reach trucks, tow tractors, automated transport systems and sweeper/scrubbers,’ says Krüger, describing the extensive applications for the drives. Users can work reliably for lengthy periods, even with smaller batteries.

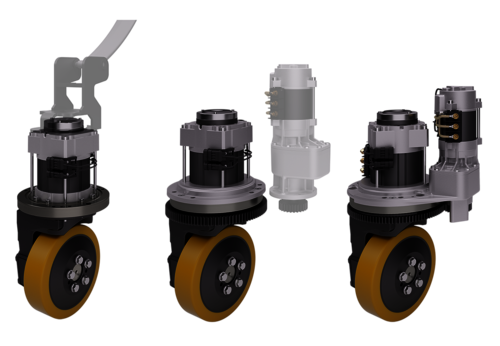

Various steering options

ABM Greiffenberger offers the bevel gearbox drive units for wheel diameters of 230 and 254 mm based on power output, speed and load capacity: Gearbox ratios and motor performances can be tailored precisely to given applications. The compact TDB series offers drive torques of up to 750 Nm. ‘It can be equipped with various steering options,’ says Krüger. The manual steering system, for example, is suitable for direct mounting on the drawbar. The user receives a space-saving, robust and accordingly long-lasting solution. An electric power steering system can be realised with external steering via spur gear. If necessary, ABM can supply a zero position sensor for the steering position as well as an absolute encoder for steering right on the traction gearbox. A third possibility is an integrated electric steering drive. The user profits from redundant steering monitoring, maximum ride comfort and a high level of safety.

For the traction area, ABM offers temperature monitoring via temperature sensor. Speed recording is done via an incremental encoder with up to 64 pulses per revolution. All AC traction motors offer energy recuperation via regenerative braking to save energy. An electromechanical holding brake is integrated for parking and emergency stopping. Krüger says: ‘With this diversity of functionalities and possible combinations, we support both developers of individual applications and OEM project managers of cross-fleet platforms with suitable drives.’

Systems Supplier with high Level of Development Expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus, we are not a standard supplier and offer our customers a measurable added value.’

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source.

As a system supplier, ABM Greiffenberger offers all drive components for forklift truck traction, lifting and steering from a single source.

Manual or electric steering versions are available. A fully integrated drive unit can be supplied and consists of electric steering and redundant steer motion monitoring directly on the drive wheel.

Bevel Gear Drives TDB 230 with integrated electric steering: Highest integration and impressive driving comfort and safety.

Drive Solutions for Mobile Applications in Material Handling

>The electrification trend is just taking off in mobile applications for material handling. Electric drives are dynamic, efficient, powerful and above all reliable. They are thus suitable for forklifts, automated guided vehicles (AGVs) and pallet trucks. ABM Greiffenberger supplies the appropriate motors, gearboxes and electronics developed and manufactured in-house – and adapted to the individual application. This makes the drive specialist from Marktredwitz a valuable partner for customers with diverse intralogistics applications.

Many things are moved in and around a logistics centre – and wherever this happens, drives are required. It starts with employees coming to work in electric buses. Lorries transport goods to the receiving point – drives for auxiliary units such as hydraulic pumps, compressors and fans are needed here. When the lorries drive up to the dock, rolling doors open and close so that the employees can load or unload. By means of pallet trucks, forklifts or AGVs, the goods are moved to pallet and accumulation roller conveyors, which bring them to the high-bay storage area. Ergonomic lift assists are used for goods handling and machines are used for cleaning the production floors. ‘We supply suitable motors, gearboxes, brakes and inverters for all these applications – from a single source,’ says Michael Lühmann, Head of Sales & Marketing at ABM Greiffenberger. ‘This makes us a systems supplier for the entire intralogistics field.’

The drive specialist offers ready-to-install plug-and-play systems available as modules within a platform concept for the mobile sector. ‘We can thus easily combine gear ratio and motor size with brakes and sensors and in this way optimise customer applications. The finished solutions can be integrated into the different vehicle types,’ reports Lühmann. This is by no means always the case on the market.

ABM Greiffenberger can completely cover the functions of traction, lifting and steering with its solutions in the mobile sector. They comply with strict environmental and emission requirements, are particularly safe and are extremely responsive for precise movements even at low speeds. ‘With this we are responding to a growing market. Because electrification is advancing more and more in mobile applications in intralogistics,’ says Michael Lühmann. Electric drive systems are more sustainable and more efficient. They run reliably and smoothly, are dynamic and durable, and offer safety. For that reason it is only logical for electric drives to be increasingly employed in a number of applications.

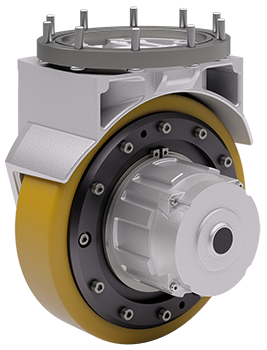

Hub wheel drives with electric steering

The drive specialist offers three gearbox types for mobile applications – including the robust TDH series hub wheel drives. This type of drive is extremely compact because the drive components are integrated into the drive wheel. The user profits from high static and dynamic wheel loads. Thanks to high wheel torques at low speeds, the user can precisely manoeuvre and drive up inclines with, for example, pallet jacks, aerial work platforms, AGVs or sweeper/scrubbers. ‘We also offer the hub wheel drive with electric steering,’ says Dipl. Ing. Mayk Krüger, Head of Mobile Drive Technology. With its low installation height, this version is ideal for forklifts and automated guided vehicles. The user benefits with the hub wheel drive with electric steering from a precisely controllable and efficient AC motor technology. It brings a torque of up to 300 Nm to the wheel and has a drive torque of 360 Nm. The redundant steering sensors provide for precise steering. Moreover, the drive is durable, maintenance-free and highly loadable.

Bevel Gearbox Drive Units: Innovative platform concept

With the bevel gearbox drive units in the TDB series for wheel diameters of 230 to 254 mm, the systems supplier has efficient components featuring high performance and low energy consumption in its portfolio. The ready-to-install systems are modularly designed and are available as a platform concept. The complete solution comprising the motor, gearbox and sensors can easily be integrated into different vehicle types. In industrial trucks the TDB series bevel gearbox drive units provide high climbing performance and acceleration. They offer responsive and dynamic steering over the entire speed range.

The bevel gearbox drive unit is available in three versions – for example, with an integrated steering drive. The traction motor is vertically mounted in the fixed version. The operator profits from, amongst other things, redundant steering monitoring, maximum integration and excellent ride comfort with high safety.

ABM Greiffenberger also supplies the bevel gearbox drive unit for manual steering. The vertical mount of the traction motor in the rotating version is designed for direct drawbar mounting. This robust and durable solution features space-saving installation.

‘Application-specific steering is also possible; customers can also combine the TDB bevel gearbox drive units with their own steering drives,’ says Mayk Krüger. They are thus suitable for electric power steering systems and can be controlled via spur gear. A zero position sensor can optionally be attached for calibration of the steering positions.

Speed recording in this series is done via an incremental encoder with up to 64 pulses per revolution. There is also an option to use the AC technology with regeneration capability. An electromechanical holding brake is integrated for parking and emergency stopping.

Parallel shaft gears: Quiet and efficient

The TDF series helical gearbox drive units offer an especially high efficiency, low wear and quiet running even at high loads. ‘We achieve this via the high-contact-ratio helical gear technology,’ explains Lühmann. The gearboxes are suitable for use in pallet jacks and three-wheel forklifts, for example. ABM manufactures the gearboxes from die-cast aluminium. Thus customer-oriented solutions can be provided at a good price-to-performance ratio. The design and the matching of the material to the application make sizes 200 mm and 230 mm light and stable. Speed recording is done via an incremental encoder with up to 64 pulses per revolution.

Systems supplier with high level of development expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus we are not a standard supplier and offer our customers a measurable added value.’

One example of an individual development is an electric differential axle for forklift trucks and transport systems. Precisely adapted to the application, the differential axle has optimised interfaces and can thus easily be implemented into the vehicle.

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source. Even complex prototypes can be produced at short notice with additive manufacturing.

‘Our drives offer high performance and system availability,’ stresses Lühmann. This is especially important in material handling because the vehicles are often used in two- or three-shift operations. Reliability is extremely relevant here. Operators therefore rely on drives that are maintenance-free, robust and durable. ‘We consistently pursue our goal of not only delivering high-quality drive solutions, but also supporting our customers in the capacity of a partner with engineering and manufacturing expertise,’ says Michael Lühmann.

The platform concept of the TDB bevel gearbox drive units offers users numerous options:

Depending on the application case, integrated, manual or application-specific steering can be selected.

Plug-and-play for automated guided vehicles – the efficient TDH230i hub wheel drive with electric steering enables precise and safe manoeuvring.

Electric differential axle for forklift trucks and transport systems – an individual drive system specially adapted to the specific application.

KYBURZ Switzerland AG relies on the know-how and drive technology of ABM Greiffenberger for its electric vehicles

>KYBURZ Switzerland AG with registered office in Freienstein near Zurich in Switzerland is an international leader for high-quality mobility and transport solutions used e.g. by postal operators for delivery of letters and parcels. When it comes to drive technology, the provider relies on the comprehensive support of ABM Greiffenberger, from concept to series production. ABM supplies everything from a single source.

Martin Kyburz founded KYBURZ Switzerland AG in 1991. Today, with 150 employees the company is one of the leading manufactures for urban delivery vehicles, which thanks to automatic parking brake and reverse gear arrive at their destination safely and quickly even in wintry conditions. This includes the KYBURZ DXP. The E-Mobile fleet combines the efficiency of a two-wheeler with the safety and stability of a three-wheel vehicle. DXP is used by postal operators in various countries such as Germany, Finland or Austria, as well numerous cities such as Winterthur or Montreux. However, postal and logistics companies are not the only ones relying on this environmentally friendly vehicles, the electric sport cars for leisure sector are also extremely popular and ensure lots of driving pleasure. That is why, among others, the Swiss have developed the eRod, an electrically powered racing car approved for the road.

“We offer a comprehensive service package”, says Daniel Weber, Head of Development at KYBURZ. “We develop, produce vehicles and take care of the after sale service. We also take them back after being used, process them or take care of their recycling”. Currently, over 23,000 of these electric vehicles are on the roads worldwide. Apart from the USA, the company is active in all markets worldwide.

Required: High-Performance and Efficient Drives

Users have high expectations. Especially postal services, which have to deliver their shipments quickly and reliably, require vehicles that are efficient, environmentally friendly, reliable and inexpensive to maintain. This places particularly high demands on the drives. Because the postman must be able to manage steep streets with his fully loaded vehicle and be able to accelerate at all times. Since these vehicles are used on daily basis, both acceleration and range play a major role. This requires motor performance and efficiency.

KYBURZ Switzerland AG turned to ABM Greiffenberger to manage this balancing act, this was in October 2011. As a full-service provider, the drive specialist with registered office in Marktredwitz in Upper Franconia develops and manufactures systems for stationary and mobile applications which are installed e.g., in logistics in conveyors, hoists or forklifts. In addition to modular system solutions, ABM Greiffenberger also impresses with customer and application specific drive solutions that ensure customers measurable added value. ABM works closely and in partnership with the customer. “Even before the turn of the millennium we had started to transfer our know-how from battery-powered applications to E-Mobility. Even back then we were able to implement the first customer-specific projects”, reports Jürgen Schliermann, Head of Mobile Drive Technology Development at ABM. “We recognise new trends early on - this is important, especially in a future-oriented industry such as the electric mobility. We take this into account thanks to our comprehensive development and production capabilities.”

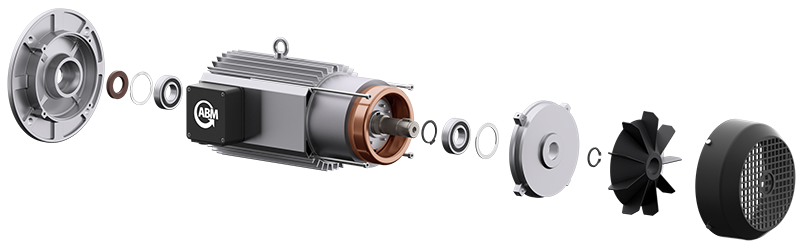

High Acceleration from Standstill

“We were looking for a reliable partner for our ever increasing quantities and for the growing demands of the users”, explains Daniel Weber from KYBURZ. “We were familiar with the high level of expertise of ABM and the good reputation of the supplier.” The drive specialist supplied the AC end shield motors for the DXP series delivery vehicles. Weighing only around 22 kilograms, these powerful three-phase asynchronous motors are quiet, environmental friendly and optimised for the stressful stop-and-go operation. They impress with their high acceleration capacity even from the standstill position, just the right one for these applications. “The weight-optimised AC end shield motors are also robust, durable and with their special design without housing they are suitable for applications with high load peaks and high dynamics”, explains ABM expert Schliermann. Heat generation is a major issue with high torques and low speeds. This challenge can be managed with the ABM drive.

It was also important for KYBURZ to have a drive which requires little or no maintenance. In addition, the motor draws the energy from maintenance-free lithium iron phosphate batteries. External drive controllers assume the power supply and speed / torque control. Thanks to the optimised interaction with the controller the system is very well regulated, ensuring high level of power density. “We can deliver a light, efficient and compact drive that optimally accelerates, provides a good driving dynamic and therefore also achieves a long range”, says Schliermann.

Emotions Instead of Emissions

Thanks to the good cooperation and reliable products ABM drives are also installed in eRod. The 600 kilogram vehicle achieves a top speed of 120 km/h and a range of around 180 kilometres. Thanks to the powerful electric drive the sports car provides the passionate driver with maximum driving pleasure. “We had already developed our ring rib motor, and only had to adapt it to the electrical properties”, reports Jürgen Schliermann. In contrast to the end shield motors, the compact and only about 43 kilogram AC drive has a housing. There is also the ring-shaped design of the ribs. Both protect the motor against dirt and ensure a good heat dissipation. It is installed on the differential axle transversely to the driving direction. “Thanks to this installation position we have adapted the ribs of the drive in such a way that an optimal air cooling is ensured”, explains Schliermann. This solution is suitable for journeys with high load peaks and high continuous performance”. In other words, perfect for a vehicle which is not only emission-free but with which the driver can also be quickly on his way. The dynamic drive accelerates very quickly even from a standstill position. Voltage supply and speed / torque control are performed by an external control. The ring cooling fin motor is also optionally available with higher protection class (IP6K9K). In addition to a cost-effective solution the performance values were particularly decisive for KYBURZ.

Benefit Across the Board

“With ABM drive solutions we have achieved optimal performance across all our applications”, gladly mentions Weber. “This also includes higher temperature resistance, allowing vehicle operation at performance limits for longer periods.” KYBURZ is very satisfied with both drive solutions: Because postal vehicles are in use daily, the eRod usually only occasionally: ABM drives are suitable for short, dynamic stretches as well as for the continuous operation in postal services.

A cooperative relationship has developed out of the project. “We are always get quick, competent support. Should modifications be required, together we always quickly find the suitable solution”, describes Weber. “It is thanks to this cooperative partnership that we always find a perfect system solution. Thanks to our extensive experience with this drive technology our development cost is usually held within limits”, adds Schliermann.

For its part, ABM opted for a sustainable delivery vehicle of DXP series for its energy efficiency and zero emission. “We use the vehicles for journeys between our two plants in Marktredwitz in Upper Franconia. Our employees are also excited” happily reports Schliermann.

The maintenance-free AC drive is suitable for journeys with high load peaks and high continuous performance.

Figure: ABM Greiffenberger Antriebstechnik GmbH

The already optimised air cooling is further supported by installing the drive transversally to the driving direction.

Please also have a look at our video.

Figure: ABM Greiffenberger Antriebstechnik GmbH

The emission-free eRod provides maximum driving pleasure both on and off-road.

Figure: KYBURZ Switzerland AG

Graduate Engineer (University of Applied Sciences) Jürgen Schliermann, Head of Mobile Drive Technology Development at ABM Greiffenberger

Figure: ABM Greiffenberger Antriebstechnik GmbH

Daniel Weber, Head of Development at KYBURZ Switzerland AG

Figure: KYBURZ Switzerland AG

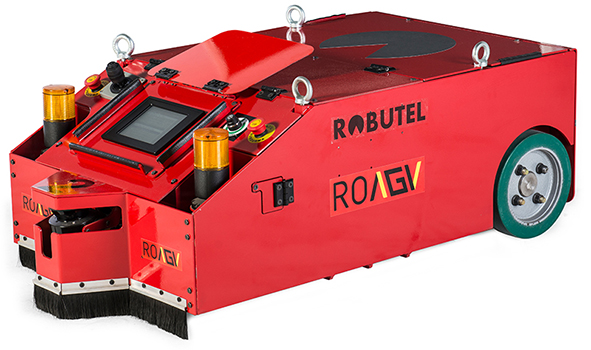

All Clear for Automated Guided Vehicles (AGV)

>Automated guided vehicle (AGV) systems can increase efficiency in production and logistics. To do so, however, they have to be powerful, safe and flexible. ABM Greiffenberger presented a series of extremely compact and space-saving gearboxes designed specifically for use in automated guided vehicles. They enable reliable and energy-efficient operation on factory floors and in warehouses.

ABM offers efficient gearboxes for various vehicle concepts. These include towing vehicles, undercarriages, upgraded forklifts and assembly platforms. ABM developed particularly compact parallel shaft and angular gearboxes, which can be easily integrated into the often tight spaces of automated guided vehicles.

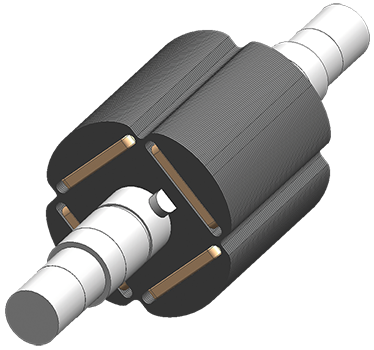

The two- and three-stage units are available with high reductions, low backlash and high encoder resolution. They are designed for low speeds and enable exact vehicle positioning. Different steering versions are used depending on the drive unit design, e.g., via electronic differential control of two motors for curved paths. For complex driving maneuvers, forward and backward motion, lateral travel or rotation when stationary, one or more drive wheels can be steered electrically.

KG series bevel gears with output torques of 60 to 800 Nm are included among the versions that are particularly well suited to use in AGVs. FG series parallel shaft gearboxes range from 50 to 2,000 Nm. ABM also has helical gearboxes in its portfolio with output torques ranging from 30 to 2,080 Nm. High wheel loads of up to 25,000 N are provided by hub wheel drives (TDH series) offered in four versions with output torques from 360 to 2,000 Nm and of robust design. Through the integration of the components into the drive wheel, the ABM designs excel as traction drives with particularly efficient, space-saving force transmission. Bevel gear drives type TDB can be supplied with electric steering upon request. They are available with static wheel loads of up to 16,000 N and in the different versions cover a range from 435 to 2,000 Nm. Type TDF parallel shaft gearboxes with a performance range of 435 to 1,400 Nm reach static wheel loads of up to 17,000 N.

The high wheel torques at low rotational speeds facilitate traveling on slight inclines and enable precise maneuvering. Additionally, users save costs: Thanks to the high wheel loads, there is no need for separate support of the wheel axle.

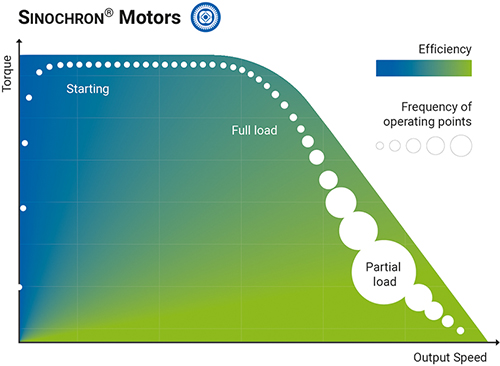

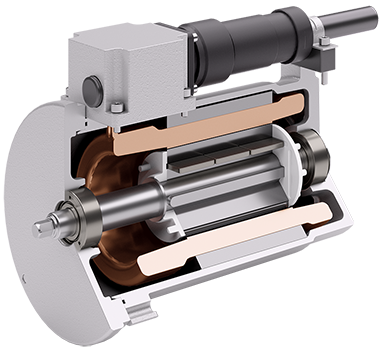

SINOCHRON® Motors for Long Battery Life

Compared with forklift drives, automated guided vehicles do not require high starting torques for inclines because they are usually used on level factory floors. Autonomous operation batteries with 48 or 24 volts are frequently used. Permanent-magnet synchronous motors have proven themselves in low-voltage applications and are recommended for use here. ABM offers the SINOCHRON® series with a continuous output of up to 13 kilowatts for this use. This series is characterized by its compactness and high efficiency. SINOCHRON® Motors are environmentally friendly. They surpass the requirements of Super Premium Efficiency class IE4. Users can meet future legal regulations with these advanced standards. The drives possess a high power density and provide for long battery life in daily use. In addition, the series is compact and can easily be integrated into transport systems.

Permanent focus on customer benefit

ABM Greiffenberger is present in the AGV sector as a system supplier who offers a high-level of customer support, development expertise and turnkey solutions: all products are designed in-house, and even complex prototypes can be quickly produced via additive manufacturing. Modern testing technologies and a laboratory for materials analysis and motor dynos ensure consistent high quality. The parts are produced on state-of-the-art machines and machining centers; robot-controlled manufacturing cells guarantee consistent series quality. Innovative products arise out of close customer relationships and intense market monitoring. ABM uses its modular and extensive portfolio to develop application-tailored, space- and cost-optimized systems.

Angular gear with low-voltage motor from ABM Greiffenberger for efficient use in automated guided vehicles.

Type TDH 230 wheel hub drive from ABM Greiffenberger with high wheel loads of up to 25,000 N.

In this towing vehicle angular gears with low-voltage motors are used to ensure powerful and precise driving performance.

ABM Offers Energy-Efficient, Liquid-Cooled Motors for Long Operation

>ABM DRIVES INC. added liquid-cooled motors to their comprehensive program of efficient drive technologies for various industries. This motor excels with high power density at minimal space requirement, energy efficiency and long operating time.

Users can reliably operate this motor over a long period with high output devoid of overheating. ABM DRIVES INC. offers these motors in IEC frame sizes 80 to 160. Outputs up to 100 kW are feasible and if required they can be easily controlled with ABM inverters. Additionally, it is possible to set a constant operating temperature resulting in uniform elongation. This means the motor can be fitted in µ-accuracy in its application – an advantage that considers the ever-increasing demand for smaller space requirements.

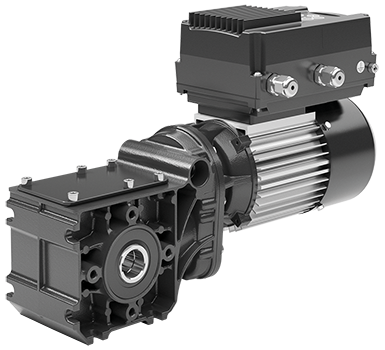

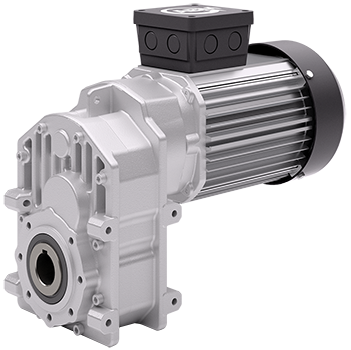

Depending on the application or customer needs, cooling can be accomplished by water, oil or refrigerant. Radial cooling results in an extremely efficient motor but axial cooling is simpler in design. Liquid-cooled motors can be combined with ABM straight shaft, parallel shaft and right-angle shaft helical gearboxes. The user can pick flexibly from the complete ABM drive portfolio. The motor lends itself for industrial applications such as textile machinery but also for mobile uses such as construction machinery. In addition, they impress in powerful electro vehicles and watercraft.

ABM presents itself as a systems supplier that can deliver complete drive solutions from a single source. The company takes over full systems responsibility from specification to manufacturing. In addition, the specialists from the town of Marktredwitz deal with the systems integration, so customers receive solutions with additional benefits. ABM makes sustainability an important consideration in the strategic direction through an emphasis on the protection of resources, high energy efficiency and minimal emissions during operation.

Straight shaft, parallel shaft and right-angle shaft helical gearboxes combined with ABM motors can also be supplied industry and application-specific with inverters. They are equipped optimally with different bus systems and guarantee network interconnectedness. This prepares the ABM drives system for the Industry 4.0 requirements.

The liquid-cooled motors are suitable for a variety of industrial applications as well as mobile applications.

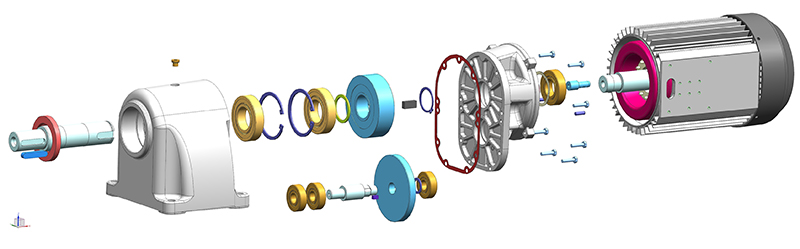

Gearbox and Electric Motor Drive Units for Forklifts

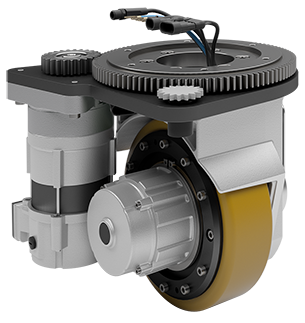

>ABM Greiffenberger develops efficient forklift drives for traction, lifting and steering for its customers. As a system supplier the company from the Upper Franconian town of Marktredwitz offers all drive components from a single source. TDB series bevel gears and TDF series parallel shaft gears were some of the products that could be seen at LogiMAT. They are powerful, energy-saving and reliable in daily use.

Fast movement and smooth transport of goods in various sizes and weights are important factors in intralogistics. Accordingly there are also high demands on the drive technology. Gearboxes from ABM Greiffenberger feature impressive driving comfort and safety. They meet strict environmental and emission requirements. In the expanding electrification, that amongst other benefits provides noise reduction in storage and warehouse uses, the company sees further growth in market potential.

The gearbox solutions from ABM make high gradeability and acceleration of pallet trucks possible. Even at low speeds forklifts can be controlled precisely – with highly dynamic steering. Thus operators can maneuver them more easily, even in tight spaces. ABM offers ready-to-install plug-and-play systems which are available in modular form according to a platform concept. Motor, gearbox and sensors can easily be integrated into different vehicle types.

TDB series bevel gears can be used for a variety of purposes.

They are found in reach trucks, tow tractors, autonomous transport systems and sweepers/scrubbers. The components are powerful and highly efficient. Even with small batteries, users can work reliably for long periods. The TDB series was extended with a drive that can handle output torques up to 750 Nm. With an unchanged installation space, the drive torque was once again increased by 15% over the predecessor model. ABM Greiffenberger designed the series to be compact. The vertical motor mounting and the further optimization of gearbox components such as gearing and housing lead to a small envelope circle: the user benefits from a space saving gearbox installation.

ABM Greiffenberger developed the bevel gearboxes for wheel diameters of 230 and 254 mm and a wide range of applications and great flexibility: application-specific combinations of gear ratio and motor output can be easily realized. The series is also available in combination with an integrated steering drive and redundant steering monitoring right on the drive wheel. For ‘driving’ ABM offers temperature monitoring via a temperature sensor. Motor speed recording is done via an incremental encoder with up to 64 pulses per revolution. Use of a regenerative AC technology is also possible. An electromechanical holding brake takes care of parking and emergency stopping. The overall design thus offers a wide variety of functions and combination options. Now both developers of customized individual applications and OEM project managers for cross-fleet platforms have the ideal drive for their respective application available.

TDF series: Quiet Running and Plenty of Powe

TDF series parallel shaft gears impress through their high efficiency, quiet running and longevity. Especially quiet running is stressed over and over by users. This is made possible by the highly optimized helical gear technology used by ABM Greiffenberger. The gearboxes are suitable for use in pallet trucks and three-wheel sit down forklifts, amongst others. The die-cast aluminum alloy housings used with sizes 200 and 230 mm ensures lightness, high stability and corrosion resistance. The housings for versions with wheel diameters 254 and 471 mm are are made out of robust ductile iron.

ABM offers the TDF series with a motor output of 1.2 to 4.7 kW. The maximum wheel torques range from 435 to 1,400 Nm. The gears can be supplied with different gear reductions based on the applications. ABM Greiffenberger can develop customer-specific housings for a cross-fleet platform design and large vehicle volumes. Even with the TDF series, precise motor speed recording for smooth deployment is possible.

System supplier with high-level development expertise

With the trade fair presentation, the drive specialist displayed its strengths as a system supplier with a high level of consultation and development expertise. It supplies all products, both motors and gearboxes, from a single source. With additive manufacturing even complex prototypes can be quickly produced. Modern testing technologies, motor dynos and a laboratory for materials analysis ensure high quality in design and engineering already at the development stage. With its in-house aluminium die-casting foundry, the company has attained a prominent position in the production of gearbox housings. The parts are produced with high process reliability on automated and flexible machines and machining centres. Robot-controlled manufacturing cells and winding lines enable consistent series quality.

ABM Greiffenberger has always paid special attention to ensuring close customer relationships and intense market monitoring. Based on its modular and extensive portfolio, the drive specialist develops application-tailored space- and cost-optimised systems with maximum benefit to the user.

Figure 1: Type TDB 230/254 Kombi bevel gears from ABM Greiffenberger can be used for wheel diameters of 230 and 254 mm.

Figure 2: The high-contact-ratio helical gear technology used in the TDF parallel shaft gear series from ABM Greiffenberger guarantees maximum efficiency and quiet running.

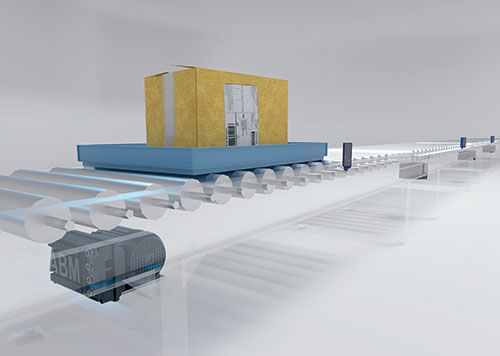

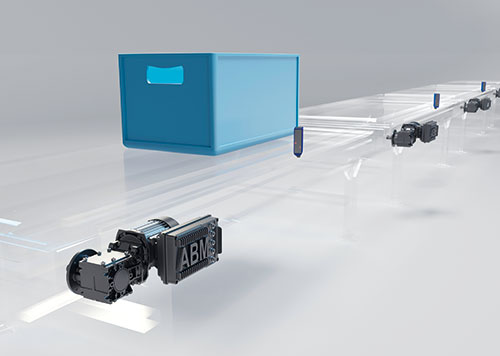

Industrial / Conveying

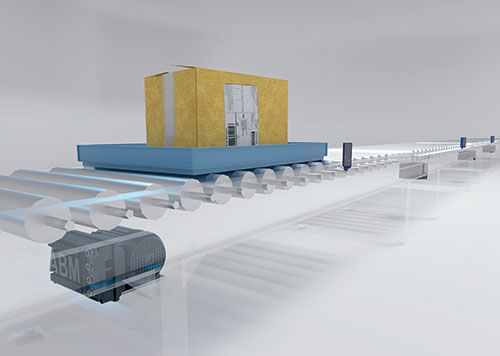

Efficient and Economical Horizontal Movements

>One of ABM Greiffenberger's product innovations is the highly integrated drive system for roller conveyors. During development, the specialists focused on making it compact, efficient and economical. This provides users with a particularly powerful and productive solution for horizontal conveyor technology.

The drive system for roller conveyors consists of a synchronous motor with an integrated controller. It has a rated output torque of 4.5 Nm with almost double the overload capacity and can move loads of up to 180 kilograms. The direct drive is a complete one-piece motor-inverter unit. This universally applicable new development is suitable for a wide range of container conveyor technology applications, including roller conveyors and curved belts.

One for All

ABM covers all common requirements in container and pallet conveyor technology with one motor. This allows system integrators to reduce complexity and the number of variants, which has a positive effect on overall costs. The drive can be easily integrated into specific application thanks to the various mounting options. Due to the high temperature range of -30 to +40 degrees Celsius, it is also predestined for deep-freeze storage.

ABM has optimized the motor technology and thus increased the energy efficiency to a maximum – this reduces the CO2 footprint. The overall system is also sustainable and resource-saving thanks to an optimized use of materials. Another advantage for the operator is the rapid return on investment: the reliable and efficient performance of the sensorless controlled drive also saves significant costs. As a result, this system solution works without the encoders, which are cost-intensive and prone to fail.

The drive specialist has designed all of the controller's connections to be pluggable. This significantly reduces the installation effort. The controller is easily controlled via the integrated multi-protocol Ethernet interface. System updates are also readily available via this interface. There is also a predictive service module: Machine-to-machine communication enables predictive maintenance and therefore smooth operation of the system - the user benefits from very high availability.

Also for high loads

As an intralogistics partner, ABM also offers complete system solutions for extended bin or pallet conveyor technology, i.e. for transporting loads of up to one ton per load carrier: Intelligent combinations of motor, gearbox and controllers from the modular system reduce the number of variants here too. The motors can be combined with angular, helical and parallel shaft gearboxes. This allows users to minimize their stock and still have the right component on hand quickly when required, another substantial benefit.

The new highly integrated drive system for roller conveyors impresses with maximum efficiency and economy.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

Measurable Customer Benefits for a Competitive Advantage

>In every industry - often even within a product range - very specific requirements apply to the drive solutions used. Only when these are fully integrated, it is possible to achieve the optimum level of performance and efficiency. With its comprehensive know-how, ABM develops and manufactures electric motors, gearboxes and controllers. With its broad product range and high level of manufacturing integration, the full-range supplier finds the optimum solution for every requirement.

ABM defines performance not only just by torque, but above all by the measurable usefulness to customers. With its engineering expertise and state-of-the-art testing technologies, the drive specialist develops a broad technology platform for motors, gearboxes and controllers. Using an intelligent modular system, the supplier can adapt the various gearbox designs to the respective application and provide the user with a quickly available and cost-efficient drive solution in terms of functionality and efficiency. ABM also offers concepts adapted to specific industries. ABM is also a development partner for individual system solutions that are precisely tailored to a specific application.

These include, for example, generators that are installed in a truck axle module. This module generates energy while the trailer is in motion in order to supply cooling units with CO2-neutral and quiet electricity. The two built-in generators provide double the power and reliability. ABM has designed the housing specifically for the application to ensure optimum air cooling. This solution is designed in protection class IP6K9K. This means that the housing is dust-tight and can be cleaned under high pressure. The generators are optimized and compactly housed in the axis. Durable, robust and efficient, they form a reliable basis for sustainable and powerful energy generation.

ABM has developed another solution for medical and rehabilitation technology. Special drives are often used in these areas, which have to combine many functionalities in a very small space with very high demands on safety, precision, comfort and reliability - for example in stair lifts. In addition to the travel movement along the stairs, seat leveling is also required to compensate for different gradients. The two functions of travel and leveling are conveniently located in one drive unit. And because the housing can absorb external forces, this solution requires fewer components. The drives also run particularly quietly and smoothly. The drive specialist supplied a compact unit comprising motor, gearbox and controller from a single source.

For highly efficient pump systems, the ABM engineers designed a pump and gearbox housing from just one part. The drive solution is precisely adapted to the required function, interfaces are eliminated and the installation space is used to the maximum. ABM thus demonstrates a very high level of system integration. The pump can be operated using a special eccentric mechanism. The combined gear and pump lubrication ensures sustainability. This unit is also easy to service and maintain.

ABM has also tailored compact and safe drives for construction elevators precisely to their function. The interface is designed specifically for the application. Because load-bearing and guiding elements are integrated into the gearbox housing, the drive not only moves the construction elevator, but also ensures that the cage is held securely and runs reliably with guidance. The drive can be installed quickly and easily thanks to plug-and-play. And because ABM was able to reduce the number of components, the user saves costs.

Customized system solution for the electrification of a truck refrigeration unit: maximum emission reduction and efficient use of kinetic energy when driving and braking.

Precise, convenient and reliable: Drive units for stairlifts.

Compact and safe drives for construction elevators: The gearbox housing incorporates load-bearing and guiding elements.

All from a single source

>ABM Greiffenberger supplies complete drive solutions for intralogistics. If necessary, the systems supplier can adapt the solutions, consisting of motors, gearboxes, brakes and frequency inverters, for specific applications and customers. ABM works closely and in partnership with the customer. The solutions are used in applications including automated logistics systems with conveyors, lifting equipment and forklift trucks as well as automated guided vehicles (AGVs). The customer receives everything from a single source.

‘As a full-range provider of drive technology, we develop and manufacture tailored drive solutions for intralogistics that can be optimally integrated into the respective applications,’ explains Stephan Thoma, product manager for inverters at ABM Greiffenberger. One such solution is the highly efficient Sinochron motor. The permanently excited synchronous motor can be used, for example, without a gearbox as a direct drive in container conveyors for small loads of up to 180 kg. The motors have especially high efficiencies in the part-load operational range in which the drives in the systems are primarily operated. Typical travel speeds are 0.3 to 1.5 m/s.

‘Thanks to its special design, the series is perfect for operation with sensorless control. In addition, even the smallest IEC frame size of 63 can already reach nominal torques of 4.5 Nm. This drive solution differs from the induction motor by a short-time overload capacity that is approximately twice as high,’ reports Thoma. Because of this power density, ABM can make the motor series more compact. This is a clear advantage for the design engineer, who usually receives a smaller drive and can thus reduce the installation space and energy consumption. Via the sensorless speed control, the control system calculates the rotor speed as well as the rotor angle at a given time from the electrical feedback. With this information, the currents for torque generation can be fed precisely to the motor. As a result, even without an expensive encoder, the Sinochron motor has outstanding control characteristics over a large speed control range. Because the drive does not require any sensors, it is also more robust. This ensures maximum system availability – a clear advantage for the total cost of ownership. Depending on the application, the service life of the drives can reach 50,000 hours.

‘Our Sinochron motors are energy-efficient and can be operated over a wide temperature range,’ reports Thoma: ‘Our customers can use the series at temperatures of -30 °C to +60 °C and thus even in deep-freeze storage facilities.’

Even for Heavy Loads with added Gearbox

For extended container or pallet conveyor systems, i.e. for transporting loads of up to a tonne per load carrier, ABM combines its motors with helical, parallel shaft or angular gearboxes. Specifically for these applications, ABM has supplemented its parallel shaft gearbox series with the two compact two-stage types FG182 and FG282, offering nominal torques of 180 Nm and 280 Nm respectively. Users benefit from high permissible radial loads and universal mounting options for the parallel shaft gearboxes. Hollow and solid shafts as well as shrink discs are available. The series can be supplied with or without flange. Because the gearboxes are also light and compact, they are easy to handle during installation.

ABM Greiffenberger always focuses on customer needs. ‘We select the best drive solution in terms of functionality and efficiency from our modular system for the given application,’ says Thoma. The modular principle means that even special requirements of the system manufacturer can be met with standard components. This positively affects the quality because only proven modules are used. Various mechanical and electrical interfaces are available to simplify installation. ABM realises all connections as plug-and-play solutions. Plug-in connector systems ensure fast, error-free installation.

ABM also develops completely new system solutions. The big advantages of an individual solution are the maximum added value and the permanently and considerably lowered costs that result because these drives are precisely tailored to the requirements.

Without a Frequency Inverter, nothing works

Most applications in intralogistics are implemented with speed control. ABM Greiffenberger offers an extensive portfolio of products for this, which is rounded off with two new sizes made especially for container and pallet conveyor systems. ‘With power outputs of up to 2.2 kW, we cover all the applications needed in conveyor technology,’ reports Thoma. ‘The user profits from optimal control characteristics for both induction and Sinochron motors.’ Because the frequency inverter controls the permanently excited synchronous motor without any sensors, costs are lowered and availability is increased. The devices are designed for a service life of 30,000 hours under full load in continuous operation. The pluggable connection allows for an easy and quick installation. Users receive the new frequency inverters with a protection rating of up to IP54 and an overload capacity of 250 per cent. The frequency inverters are also suitable for use at temperatures of -30 °C to +40 °C and thus even in deep-freeze storage facilities.

Frequency Inverters with numerous Features

Plug-in connections for the power supply (daisy chain principle) and control terminals/inputs make installation fast and easy. Using the Ethernet-enabled BUS systems the inverters communicate with higher level controls.

The inverters can optionally be equipped with brake choppers and the ability to control mechanical brakes. Thoma explains: ‘With sensorless control we ensure a maximum speed control range. This feature sets us apart from our competitors.’ The result is lowered costs and higher availability. The decentralised inverters can be integrated on the drive and are also suitable for field use in the vicinity of the motors as wall-mount versions. The inverters use machine-to-machine communication to connect to higher-level controls, making predictive maintenance possible. The inverters are thermally independent and require no additional fans. ‘Through the intelligent combination of motor, gearbox and inverter from our modular system, we can control the complexity,’ says Thomas. The reduced number of drive variants represents a huge advantage for users when it comes to storage, service etc.

As a systems supplier, ABM can offer drive solutions for most applications in warehouse logistics – from small roller conveyors to pallet conveyors. ‘The user receives everything from a single source,’ says Thoma.

ABM’s new inverters with power outputs of up to 2.2 kW are used in all common container and pallet conveyor applications.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

Container conveyor technology: a belt conveyor with an angular gearbox including an ABM inverter as a drive.

Chain conveyor for pallet transport: ABM’s parallel shaft geared drive unit combined with the ABM inverter is ideal for heavy loads.

Expansion of the Parallel Shaft Geared Drive Units by compact, two-stage Types

>The system provider has expanded the existing parallel shaft gearboxes (FG series) specially for the conveyor and pallet conveyor technology in intralogistics. The extremely compact two-stage solutions offer nominal torque of 180 and 280 Nm and thanks to their gear ratio and compactness they can also be used as travel drives in lifting applications. The user also benefits from highly reliable radial loads as well as the universal mounting options such as hollow and solid shaft, shrink disc, version with and without flange. Furthermore, the low weight and the compact design enable easy handling.

Systems Supplier: One single Partner for your Drive Units

As a system supplier, ABM Greiffenberger develops and manufactures application-specific and installation-optimised solutions from a predefined modular system that are perfectly tailored to the application. The specialist thus continues to pursue its goal of not only supplying high-quality and reliable drive solutions, but also supporting its customers as a development partner with engineering and manufacturing expertise. Customers receive cost-efficient complete solutions with measurable benefits.

ABM has added two-stage compact types - FG182 and FG 282 - to its existing range of parallel shaft gear units.

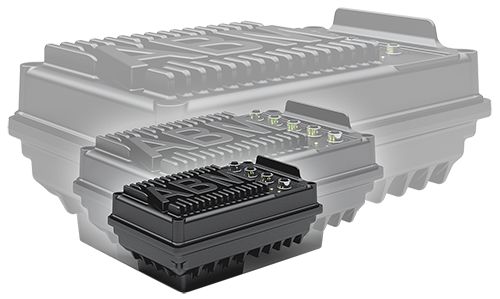

New Frequency Inverter of up to 2.2 kW for Intralogistics

>Applications in intralogistics are primarily controlled with frequency inverter. The inverter series for the conveyor and pallet technology is completed with two more frame sizes specially developed for this industry. Thanks to the power range of up to 2.2 kW higher loads can also be moved. Thus, ABM Greiffenberger covers all required applications.

The user benefits from the optimal control properties both with asynchronous as well as with SINOCHRON® motors. The frequency inverter can operate the permanently excited synchronous motor without the use of sensors. This lowers the costs and increases availability.

The inverter are designed for a service life of 30,000 hours under full load and continuous operation. Pluggable connections allow an easy and quick installation. The inverters communicate with higher-level control systems via Ethernet-capable BUS systems.

With a protection class of up to IP54 and a high overload capacity of 250 percent, the frequency inverters are perfect for accelerating heavy loads. They are also suitable for use at temperatures of 30 to +40° Celsius and therefore for use in deep-freeze storage.

Systems Supplier: One single Partner for your Drive Units

As a system supplier, ABM Greiffenberger develops and manufactures application-specific and installation-optimised solutions from a predefined modular system that are perfectly tailored to the application. The specialist thus continues to pursue its goal of not only supplying high-quality and reliable drive solutions, but also supporting its customers as a development partner with engineering and manufacturing expertise. Customers receive cost-efficient complete solutions with measurable benefits.

Two additional frequency inverters developed specifically for intralogistics applications complete the series for conveyor and pallet technology.

How ABM Greiffenberger Drives the Intralogistics World

>ABM Greiffenberger has suitable drives for all mobile and stationary applications in logistics centres. In close partnership with customers, the one-stop provider for intralogistics delivers both optimised modular system solutions and individual solutions with maximum added value for users. Visitors can find out about the powerful drives in Stuttgart) in Hall 3 at Booth B15.

Many things are moved in and around a logistics centre – and wherever this happens, drives are required. It starts, for example, with mobile applications such as electric buses that drive employees to their place of work or lorries that transport goods to the receiving point – drives for auxiliary units such as hydraulic pumps, compressors and fans are needed here. When the lorries drive up to the dock, rolling doors open and close so that the employees can load or unload. By means of pallet trucks, forklifts or automated guided vehicles (AGVs), the goods are moved to container and pallet conveyors, which bring them to the high-bay storage area. Other devices and machines, such as ergonomic lift assists for handling the goods and machines for cleaning the floors in the building, are also deployed. ABM Greiffenberger offers suitable motors, gearboxes, brakes and inverters for all these applications – for either mains or battery power supply.

These drive solutions include the Sinochron motor series, which visitors can find out about at the trade fair booth. The permanently excited synchronous motors are perfect for operation with sensorless control thanks to their special design. The advantages offered by synchronous motors are a high power density and a compact size. With efficiencies of more than 90 per cent, these motors score points in intralogistics applications in which drives are only operated at part load as well as in auxiliary units in lorries and buses.

ABM Greiffenberger has added compact and powerful liquid-cooled motors to its efficient drive technology offering. The motors possess a high thermal stability and offer exceptional protection with ratings of up to IP6K9K. They can be controlled via inverters and can be attached to all ABM helical, parallel shaft and angular gearboxes with little effort. They are ideal in areas such as mobile drive technology, where they are used, for example, as aggregate and traction drives in electric vehicles and construction machines.

Reduced Complexity

ABM offers suitable inverters that are optimally matched to the respective drive systems for all applications. They meet controllability, networking, digitalisation and connection technology as well as other requirements.

Wheel Hub Drive for AGVs – Now also with Electric Steering

ABM will present another innovation with the wheel hub drive with electric steering for AGVs and forklifts. It has a drive torque of 360 Nm; the integrated electric steering brings a torque of up to 300 Nm to the wheel. Users benefit from a precisely controllable and efficient AC motor technology. They receive complete solutions from a single source and only have to take care of the interface for the drive technology.

Chain hoists with integrated electronic control

The powerful chain hoists will also be presented at LogiMAT. They are modularly designed and provide reliable overload protection thanks to the friction couplings. The integrated electronic control is new. Via plug and play technology, the operator can easily extend the basic version to include the travel function. The new solution from ABM Greiffenberger is particularly long-lasting – wear of switching contacts does not occur. The corrosion-resistant and robust chain hoists also operate reliably in harsh environments. High-quality helical gearing enables quiet running and lowers noise emissions.

Systems supplier: One Partner for Intralogistics

ABM Greiffenberger is a systems supplier for all applications in intralogistics and develops customised, installation-optimised solutions that are optimally tailored to the respective applications. With this, ABM maintains its goal of delivering high-quality, reliable drive solutions and supporting its customers in the capacity of a partner with engineering and manufacturing expertise.

![]()

The advantages offered by synchronous motors are a High power density and compact size with efficiencies of 90 per cent and higher.

The trade fair offering will also include reliable and energy-efficient chain hoists with integrated electronic control.

The efficient TDH230i wheel hub drive is now also available with electric steering.

From 0 to 100 instantaneously

>As a systems provider, ABM Greiffenberger develops and manufactures drive systems for stationary and mobile intralogistics applications. Upon request, customers can be supplied with individual solutions allowing them to reduce their costs – and with conveyor systems quickly accelerate even heavy loads from a standstill. This is made possible by the ABM’s close cooperation and partnership with customers. But what characterises the tailor-made system solutions?

‘What requirements do manufacturers of intralogistics solutions have for drives?’ Ralf Fickentscher takes a moment to think. ‘They want highly efficient solutions that are always available and run without any problems.’ Fickentscher is head of development at ABM Greiffenberger in the Upper Franconian city of Marktredwitz. The company is a one-stop shop for drive solutions that helps customers slash costs and thus profit from a fast return on investment. ‘Our motors are extremely efficient, especially in the partial-load operational range the systems primarily operate in,’ says his colleague Stephan Thoma, ABM team leader & product manager for inverters. The fact that an electric motor can operate very efficiently precisely in partial load operational range is one of the main reasons for its higher energy efficiency. The SINOCHRON® motor, for example, is a motor that can also be operated without sensors and has a high starting torque. This is particularly important in intralogistics applications because conveyor systems often have to be able to move heavy loads from a standstill: with a speed control range of 1:200, the SINOCHRON® series can immediately apply the full starting torque to move stationary loads– virtually from 0 to 100.

Powerful and compact

The SINOCHRON® series are permanently excited synchronous motors, which, thanks to their special design, are perfect for sensorless operation. ‘They are very dynamic,’ explains Stephan Thoma. This drive solution differs from the induction motor by a short-time overload capacity that is approximately twice as high. ‘In addition, even the smallest IEC frame size of 63 can already reach nominal torques of 4.5 Nm and nearly doubling the overload capacity,’ explains Ralf Fickentscher. ‘And because the motor achieves this high power density, we can make our solutions more compact,’ As a result, the user can often select a smaller motor and thus reduce installation space and energy consumption.

In contrast to comparable drives, the motor can also be operated with 400 V – instead of just 24 V. This makes project planning much easier because multiple drives can be operated from one power supply and are switched in series according to the so-called daisy chain principle – just one power supply is needed for this. Moreover, the drives are networked via a bus system for communication and can therefore be controlled from a central point.

Via the sensorless speed control, the control system calculates the rotor speed as well as the rotor angle at a given time from the electrical measurements. With this information, the currents for torque generation can be fed precisely to the motor. ‘We achieve very good control characteristics with this without having to use an expensive encoder,’ says Thoma. And because the drive does not require any sensors, it is also robust. ‘Almost like the famous bunny. It keeps going and going and going,’ says Fickentscher. Through this, users also experience significantly lowered maintenance costs and a high system availability, both of which are important benefits for the total cost of ownership. The drives also have a service life of up to 50,000 hours.

Individual Solutions from a Modular Design

ABM Greiffenberger can also cater to the individual needs of users with the drive solutions. To what extent? ‘That depends on the requirements,’ says Thoma. ‘With our intelligent modular design, we can find the right solution for every application.’ Various gearbox designs such as angular, helical and parallel shaft gearboxes are also available and are developed, manufactured and tuned to the performance values of the respective motors by ABM. Thanks to its modular design, the drives can also meet special requirements of the system manufacturer with standard components. This positively affects the quality because only proven modules are used.

With this modular design, the systems provider also reduces the number of possible variants – ‘with it, we control the complexity,’ says Thomas. The system manufacturer can also select from different mechanical interfaces easing commissioning. The drive variants can also be reduced because the same motor series can often be used for a variety of tasks. If higher torques at lower speeds are required for high loads, the motor can simply be combined with a gearbox. Various mechanical and electrical interfaces are available to simplify installation. Many connections are realised as plug-and-play connections. This increases the system availability.

‘However, we can also design a completely new solution if the customer requests it,’ explains Fickentscher. With the individual solution, the user gets the maximum added value and a permanent, significant reduction in costs because the drive is precisely tailored to their requirements.

SINOCHRON® in container conveyor technology

Wearless direct drive, gearless, without brakes, energy-efficient and with high availability: all this is what makes the ABM solutions suitable for, amongst other things, roller conveyors that transport containers with different weights, often over several kilometres. ‘Our motors offer high efficiencies and power densities. In addition, they are ideal for tight spaces due to their compact designs. With the SINOCHRON® drives, the rollers in the conveyor systems can convey loads weighing up to 180 kilograms – and accelerate them from a standstill. ‘A high torque is required to start the load and then the drives operate about 90 per cent of the time with a partial load operational range,’ explains Thoma. Typical travel speeds are from 0.3 to 1.5 m/s.

Because the gearless motors require no oil or lubricants, they can also be used in the food industry. A further advantage of the SINOCHRON® drive is its suitability for use in deep-freeze storage facilities: the series can be used in a temperature range of -30 °C to +60 °C. ‘Established drum motors, in contrast, are only suitable down to 0 °C,’ reports Thoma.

One user who relies on this drive solution from ABM is Witron Logistik + Informatik GmbH from Parkstein in the Upper Palatinate. The single source general contractor plans, realises and operates automated logistics and material flow systems. The company assumes the logistics planning, information and control technology, mechanical design and manufacturing, and the operational responsibility. Added to that are all service and maintenance tasks for a project. ABM SINOCHRON® motors are integrated into Witron logistics systems around the world, currently in a project with a German grocery chain with several kilometres of conveyors. ‘We could reduce installation space and energy consumption with these solutions,’ says a satisfied Josef Uschold, head of development of control technology at Witron. ‘I was especially impressed with the cooperation with ABM. It was a good partnership right from the start. We always receive high-quality and reliable components.’

Also suitable for very high loads

But what if the drives have to move much higher loads – as is the case with a pallet conveyor? ‘Then we attach an existing gearbox to the motor,’ explains Fickentscher. The user can then handle loads of up to 1,200 kg and still profits from the advantages of the SINOCHRON® motors, such as a compact design, maximum torque over a large speed control range or a large number of mounting and integration options.

‘If our compact parallel shaft gearbox FGA is used in a conveyor system, it can be installed, for example, parallel to the motor shaft. This makes the U design and thus also an output shaft on the motor side possible, which makes this solution even more compact,’ says Thoma. For a helical gearbox with an axial output shaft, the motor shaft and the output shaft can be configured in a line if so required. An angular gearbox, e.g., could be mounted laterally to save space. ‘We always cooperate closely with our customers to implement their requests,’ says Fickentscher. ‘To enable higher external radial forces to be absorbed in the drive, we have pulled the output shaft mounting forward into the flange.’ This is a big advantage, e.g., for pre-tensioned belt drives or external gear wheels because the distance between the point of force application and the bearing is greatly reduced. The ABM gearboxes can also be extended to yield additional system advantages. Through the flexible installation and the additional assumption of further tasks in the application, system advantages arise: for example, several movements can be implemented with just one highly efficient motor. This saves money and speeds up commissioning.

Requirements met

‘We always accommodate our users’ requirements with our solutions,’ says Thoma. Thanks to the modified modular solutions, the customer profits from fast availability. The engineering partner and provider supports manufacturers with efficient drive solutions – in automated guided vehicles, in automated logistics systems with conveyors, lifting gear and forklift trucks or in cold storage facilities. ABM Greiffenberger offers everything from a single source. The full-range provider has more than ten years of experience in the applications. ‘More than 500,000 of these drive solutions are being used successfully in companies around the world,’ stresses Ralf Fickentscher.

When, for example, an angular gearbox is added, very high loads can be transported with high efficiency and high power density.

The pulled-out mounting of the output shaft makes the drive extremely robust.

The high energy efficiency of the sensorless drive, particularly in the part-load region, significantly lowers costs and ensures a fast return on investment.

Ideal for tight spaces: the parallel shaft gearbox with decentralised inverter and permanently excited synchronous motor (SINOCHRON®) fits compactly into the belt conveyor.

Angular geared motors also drive transport units reliably and efficiently in the logistics systems of industrial companies.

ABM Drives Offers Gearmotors for Intralogistics

>In times of e-commerce and same-day delivery expectations, fast movement of goods in warehouses is becoming ever more important. In this context, stock picking and loading plays a key role. Line powered fully and partially automated logistics facilities with material handling equipment, lifting equipment as well as forklifts and automated guided vehicles (AGVs) are deployed. ABM offers suitable system solutions for all – alternatively for line or battery power supply. For line powered conveying, loading and lifting devices they include motors, gearboxes, brakes and inverters. The latter can be networked and are gaining in importance with regard to Industry 4.0 (IoT).

Line powered systems are perfectly suited for container, box and pallet handling equipment including truck trailer loading and unloading conveyors. The range of products includes energy-efficient asynchronous and Sinochron® motors and apart from helical, parallel shaft and angular gearboxes, centralized and decentralized inverters.

Intralogistics system OEM require compact, powerful and energy efficient drive units. Integration flexibility and reliability with a long service life expectancy are a must. ABM motors and geared motors have been designed with these goals in mind and customization to make life easy for the OEM is always possible even preferred.

Systems Supplier: ONE Partner for Intralogistics

ABM DRIVES INC. is a systems supplier for both stationary and mobile applications. Customers are comprehensively supported from development to series production and receive everything from a single source. Users can select from an extensive modular system. We provide cost-efficiently and quickly application-specific adaptations. ABM assumes system responsibility and provides support in system integration for demanding and individual projects. Focus is on maximum customer benefit and intensive development activities. This results in reliable, durable and safe products that are characterized by high dynamics, smooth running and reliability and are of compact design for easy installation. With a global team of application specialists, ABM is ready to assist you in finding the perfect drive solution for your unique needs wherever your operation is located.

Figure 1: ABM powerful angular geared motors from the KG series with motor mounted IoT capable INVEOR inverter.

Figure 2: Compact and energy efficient parallel shaft gearbox (type FGA 172/173 shown) available in 2- and 3-stage versions.

![]()

Figure 3: ABM SINOCHRON® Motors excel with outstanding efficiency and exceed even the highest efficiency standards.

New, efficient INVEOR Drive Controllers

>ABM now offers INVEOR MP and MP Modular motor-mounted drive controllers. They feature impressively fast system integration, energy-efficient operation and easy handling.

The new controllers can be easily combined with asynchronous and SINOCHRON® motors as well as with all gearboxes from ABM Greiffenberger. The exclusive technology enables a speed control range of 1:200. A significant advantage here is the unique mode of operation: a sensorless, large control range. This extended range saves the user costs and greatly increases equipment availability.

The drive system offers numerous advantages in warehouse logistics. It can be configured so external connections, as well as supply or control lines, are all plug-in. Therefore, installation can be accomplished quickly and smoothly, saving the user money: no costly experts are needed. The system is particularly beneficial for applications such as modular warehouse logistics systems that are rearranged regularly.