Always in Motion

Electromobility

We keep pace with fast-moving markets with our

innovative strength and constant evolution.

In a future-oriented area such as electromobility, we stand for continuous development and rely on our competencies in engineering. We recognize new trends quickly and can incorporate them accordingly thanks to our extensive development and manufacturing options. From electric motors through gearboxes and brakes to electronics, with ABM Greiffenberger you get everything from a single source, which means an ideally coordinated complete solution. Always open to new markets and applications, we focus on the following areas, amongst others.

Driving the Future

Your Movement, our Drive

More for your Application.

Our drive solutions stand for progress and advancement, but integrated into e-scooters, for example, our products also put real innovations into motion.

ABM is exhibiting a comprehensive range of drive units at the upcoming EV Show in Detroit, MI on October 07 - 10, 2024.

Please come and join us in our Booth #1603. Our specialists look forward to discuss your material handling projects with you.

Dynamic & efficient

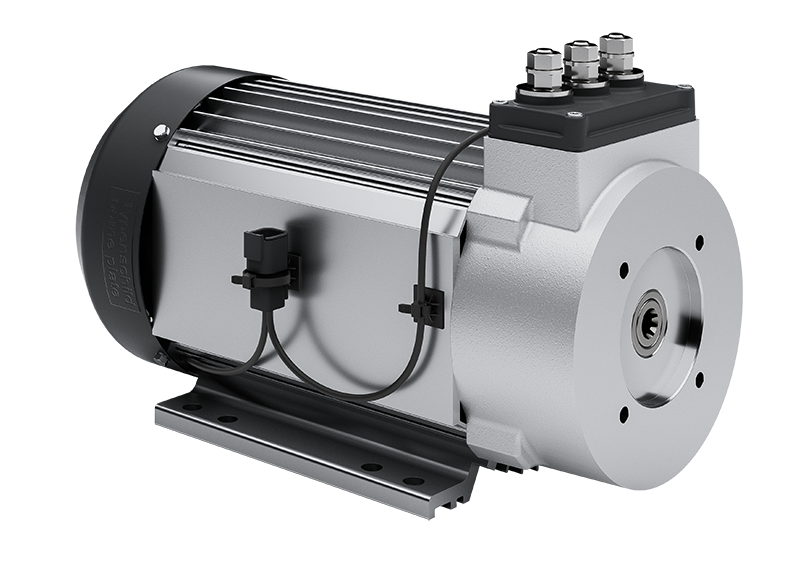

Pump Motor

Optimized Interface for SAE Pumps.

As your partner for electrification, we have developed an efficient pump motor line for mobile as well as stationary applications. These pump motors are perfectly suited to electrify bucket trucks and are available up to an output of 15 kW and a voltage range from 15 to 575 VAC. Motors can be supplied as induction (AC motors) or as highly efficient synchronous SINOCHRON® permanent magnet AC motors. The drive side end shield design ensures direct mounting of SAE pumps.

- Direct SAE A/B pump mounting

- Efficient

- High protection class

- Powerful

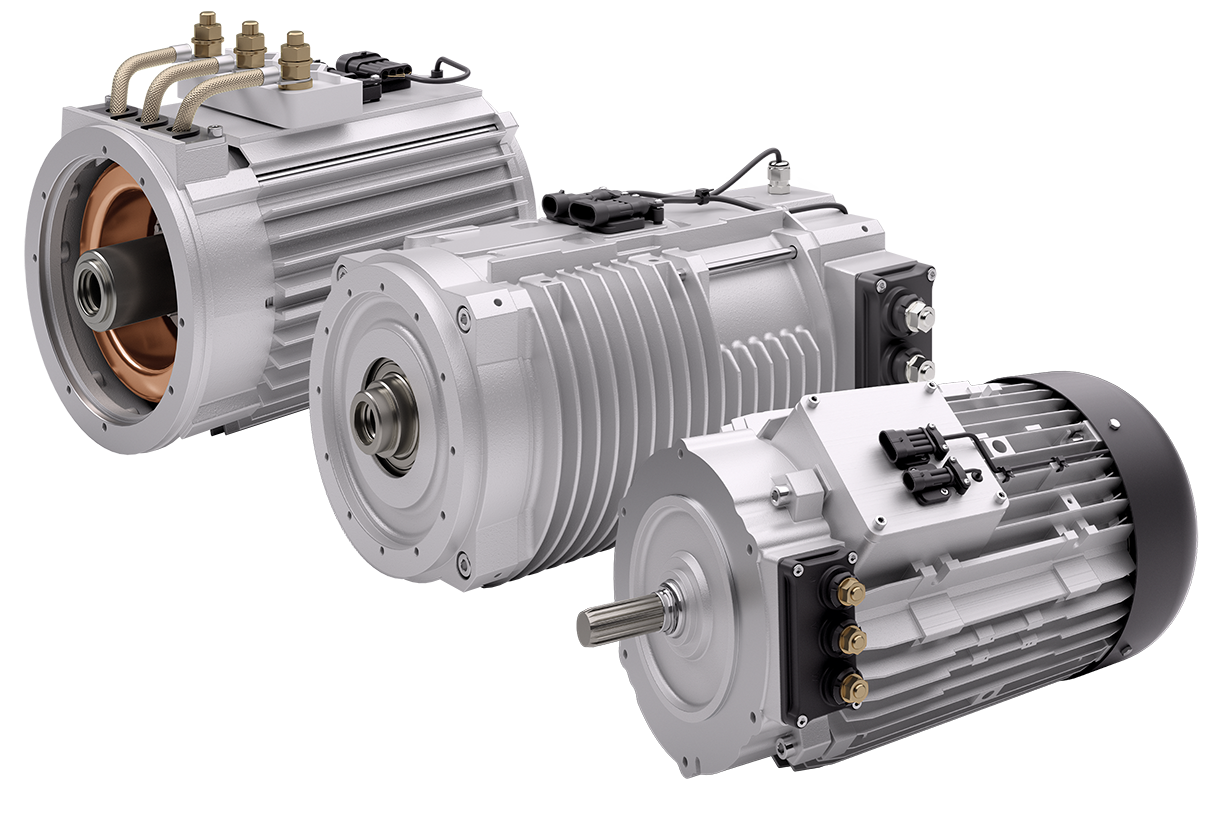

Compact & all-purpose

AC Motors with Housings

More surface for sustained power output.

Thanks to optimized cooling characteristics, the special enclosed AC motor design with housing and cooling fins enables a constantly high continuous output. As traction motors in battery-operated vehicles, for example, they are ideal for use in harsh environmental conditions and applications with high peak loads and high continuous outputs. External drive controllers assume the power supply and the speed / torque control.

- Energy-efficient

- Long driving times

- High peak torque

- Series with various available options

Robust & long-lived

End Shield AC Motors

The cost-effective alternative to enclosed motors for short-time duty.

This special design without a housing features high peak powers and an optimum price-to-performance ratio. Typical uses are applications with high peak loads and low continuous outputs, e.g. traction motors (stop & go operation) and hydraulic pumps (power on demand) in battery-operated vehicles. External drive controllers assume the power supply and the speed / torque control.

- High peak torque

- Compact design

- Series with various available options

Dynamic & efficient

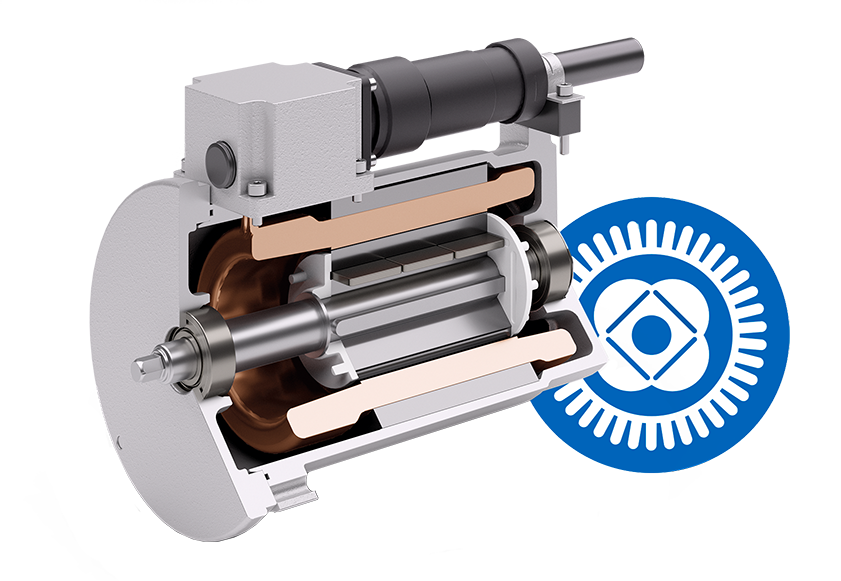

SINOCHRON® Motors

Strong magnets for efficiency and compactness.

The ABM SINOCHRON® motor is a permanently excited synchronous motor with internal magnets. The specific rotor shape generates a sinusoidal distribution of the magnetic flux. This yields special properties enabling, apart from a virtually nonexistent cogging torque, reliably regulated operation with no sensors.

- High power density

- Highest efficiencies in partial load mode

- Several sizes and lengths

- Various models

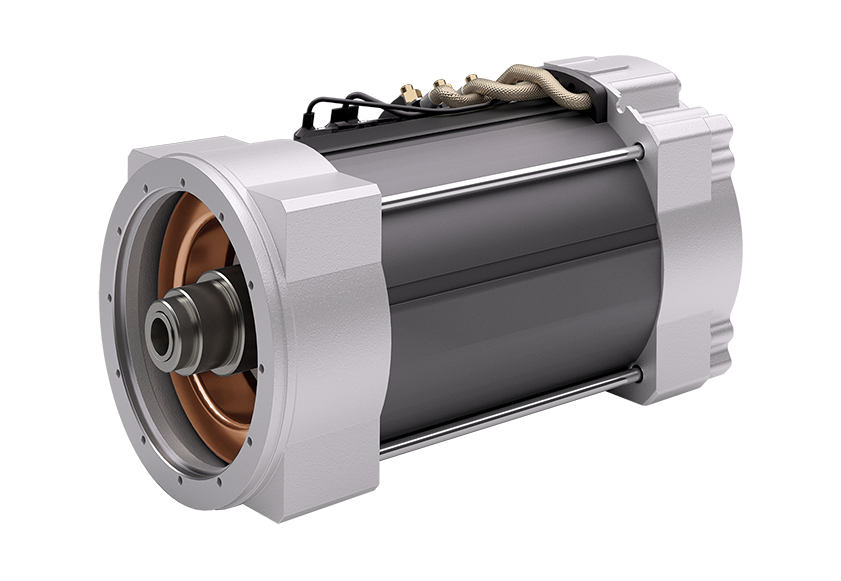

Efficient & powerful

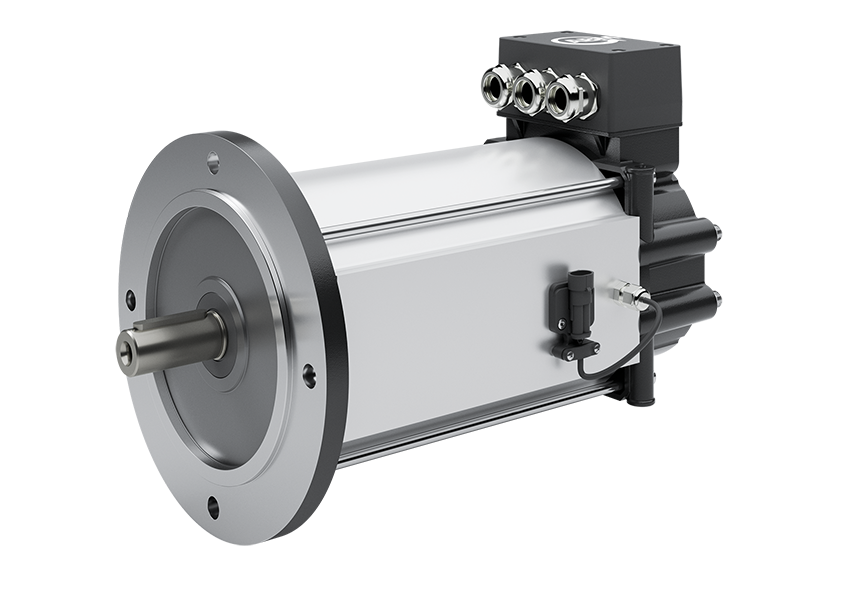

Liquid-cooled Motors

Maximum performance in a minimal space.

Liquid-cooled motors are suitable both for use in industrial applications, e.g. in the textile industry or in printing machines, and for mobile applications such as construction machines, electric vehicles, material handling vehicles or watercraft. They feature a high power density in a small space as well as extremely high efficiency and reliability. As a system solution, they can be combined with all ABM gearbox types and controlled via inverter.

- High power density

- Longer operating time

- Highly efficient heat dissipation

- Extremely compact design

- Robust: oscillation- and vibration-resistant

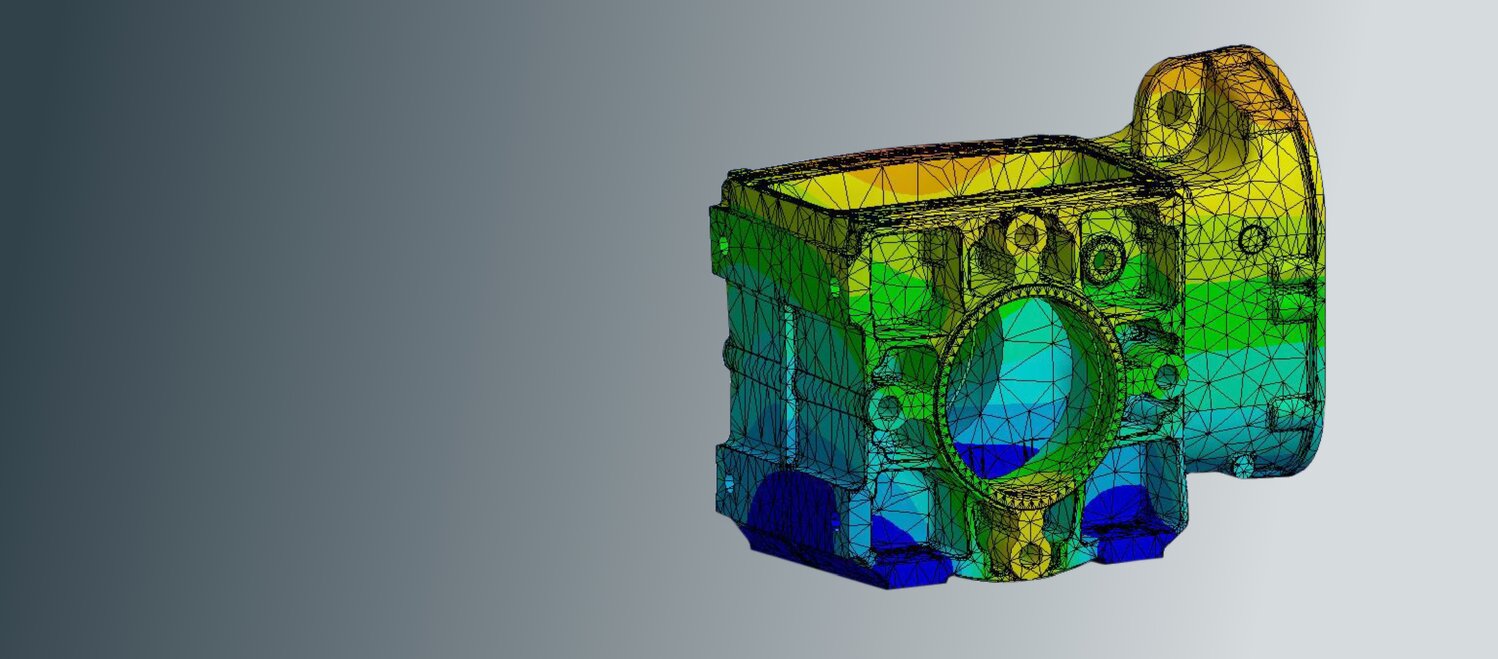

Our Engineering Competencies

Application-specific Drive Solutions

Individual, flexible and demanding: The best drive solutions engineered in Germany.

We believe that game-changing innovations can only be developed jointly.

Therefore, we are not only a supplier to our customers but an active and

passionate partner in implementation of demanding, groundbreaking

and individual projects.

High Engineering and Manufacturing Competence: In every industry –

often even within each product line – very specific requirements apply

for the implemented drive solutions.

Solution optimized drive systems from ABM consider all aspects of

the planned application. We define performance not just by torque,

but above all by the measurable usefulness to customers.

We drive the World

Choosing a Gearbox Drive and Electric Motor Supplier

When choosing manufacturing partners during a machine build, remember that there are two methods for choosing a gearbox and electric motor supplier.

One is selecting a pre-engineered unit and the other is choosing a gearbox-motor combination and integrating them into the equipment.

Pre-engineered gearmotor solutions are suitable if a design engineer doesn’t have the time or engineering resources to build a gearmotor in-house — or if the

design needs a quick setup. New modular approaches to support OEMs (and enable new machine tools, automation, and design software) now let engineers get

reasonably priced gearmotors even in modest volumes.

It’s true that one benefit to selecting a separate motor and gearbox and then combining them can less expensive than choosing a pre-engineered gearmotor.

Another benefit to this approach is that one may be able to design the most optimized gearmotor for the application at hand … because this approach also gives the

design engineer the most control over the final configuration and cost.

No matter the approach to gearmotor selection, be sure to continually improve the design by comparing predictions of performance with measurements. Then use

the result of the analysis to improve next gearmotor iteration.

Contact:

ABM DRIVES INC.

394 Wards Corner Road · Suite 110

Loveland, OH 45140 | USA

Phone: +1 513 576-1300 Send an email